What comes to mind when you think about factory automation?

Although we certainly have more robots and machines available today to complete tasks, today’s smart factories rely more on emerging technology than new hardware.

Artificial intelligence, machine learning, and data combine with physical hardware to automate processes, improve communication, and complete jobs efficiently.

What is a Smart Factory?

Deloitte calls the modern smart factory a leap from traditional automation to a “fully connected and flexible system” with a “constant stream of data” to act, learn, and improve.

The biggest difference is that all machines throughout a factory are integrated through a network or cloud system where they share data.

Today’s smart factories are only possible thanks to artificial intelligence, machine learning, and data. Using data and machine learning capabilities, the AI-powered machines can self-optimize.

These factories are much safer, more efficient, and more productive than any type of factory of the past.

4 Elements of a Seamless Smart Factory in 2021

What is a smart factory in 2021 anyways? What makes it so different than factories with automated processes of the past?

1. The Industrial Internet of Things

The “industrial internet” applies to a synergy of devices, systems, clouds, automation, and machines.

Meanwhile, the “internet of things” includes the physical objects that make this automation and data-driven communication possible.

For smart factories, the industrial internet of things includes physical sensors on machines to retrieve and share data on things like:

- Temperature

- Speed

- Fuel or charge levels

- Output

- Air filter cleanliness

- Logistics

2. Big Data Transparency

By collecting data through sensors, a fully optimized smart factory can share it between other machines, workers, and analytics tools.

Thanks to machine learning, the AI systems can learn correct patterns, report problems, identify inefficacies, and more.

Overall, the system encourages big data transparency across the entire organization at all levels: human and machine.

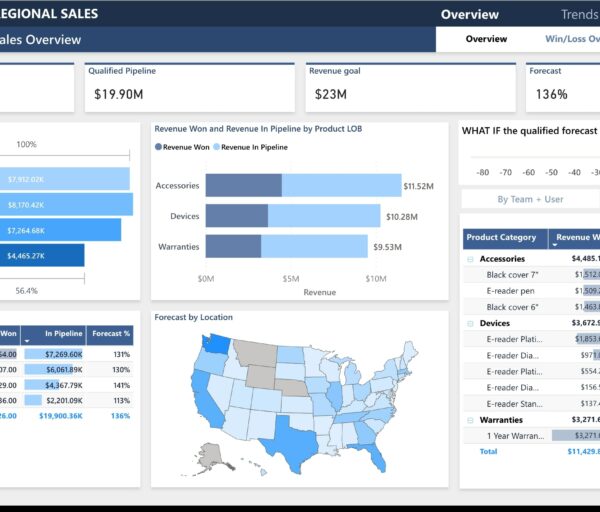

3. Data-Driven Communication, Analytics, and Visualisations

How can you tell an AI machine is spotting the right errors or running correctly if it doesn’t relay data to humans?

Every successful smart factory can’t leave machines to their own devices. Instead, use data-driven communication tools, seamless analytics, and digital signage around the workspace.

Automated data visualisations and analytics work across all levels:

- Informing shareholders and C-level about productivity and numbers

- Alerting floor workers to safety issues as soon as the machine detects them

- Keeping technicians and engineers aware of issues and areas to improve

4. Machine Learning to Self-Optimize

Artificial intelligence alone isn’t enough to run a modern smart factory. The real benefit comes from machine learning. Like humans, AI systems learn when you provide them with new information (provided they’re equipped with machine learning capabilities).

A smart factory gets better at finding and reporting problems and trimming inefficiencies the longer you use the technology. Pretty incredible!

Prioritize Data-Driven Communication in Your Smart Factory

A safe, efficient, and productive smart factory must prioritize data-driven communication. Machines already rely on integrated data communication—that’s why teams must do the same.

Smart factories rely on Valotalive’s digital signage to keep their team informed because our system seamlessly integrates with countless apps for data, team communication, analytics, and much more.